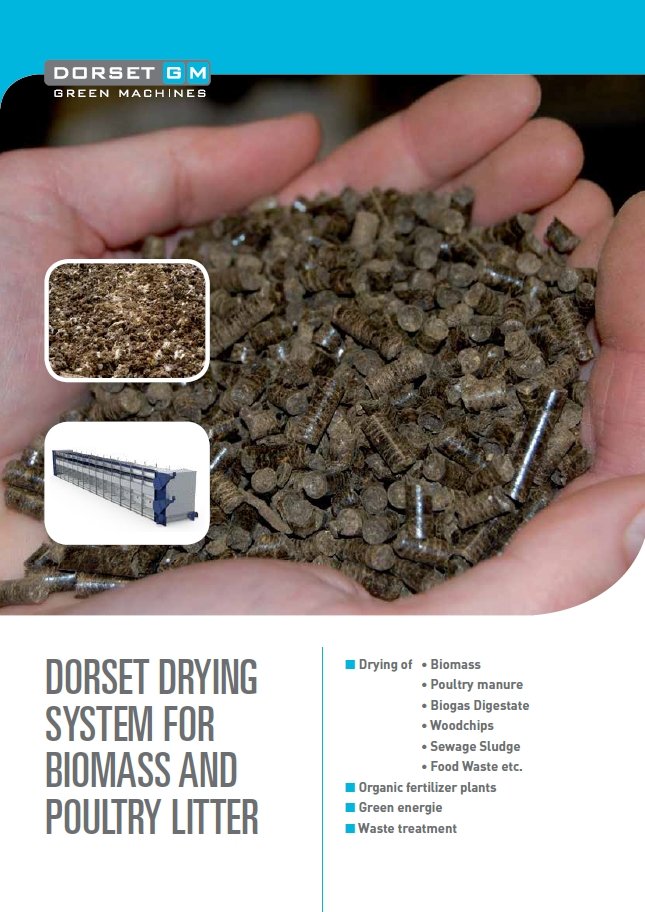

Drying biomass

Through a drying process, moisture can be largely removed from biomass. The result is a reduction in the weight of the biomass.

This leads to a reduction of the processing costs, as well as of the costs for storage and transport. The dried end product is frequently used as a plant nutrient or it can be used as a fuel. This, however, depends on the properties of the biomass that needs to be dried.

Dorset has a lot of experience with drying other biomass materials than the variants found in the menu. Some examples are grass, compost, fats and food residues. The warm air required for the use of a conveyor belt dryer, can be supplied by the use of either warm stable air or air heated in another way.

Operational 24/7

Without direct supervision

Benefits of the Dorset dryer

Low energy consumption

Highly compact and flexible

Requires little maintenance

Fully automatic operation without supervision is possible

Remixing frequently makes a pre-treatment of biomass unnecessary

Low dust generation through low air speed

Why dry biomass?

- Making good use of residual heat during the entire year

- Lower storage and transport costs

- New sales and utilization possibilities

various biomasses

It is possible to dry almost any organic waste stream. Dorset has experience with drying a wide variety of biomasses

Dorset has a lot of experience with drying other biomass materials than the variants found in the navigation menu. Some examples are grass, compost, fats and food residues.